Key 3PL Metrics and KPIs to Monitor

In today’s fast-paced, customer-centric supply chain environment, third-party logistics (3PL) providers play a crucial role in helping businesses manage inventory, fulfillment, shipping, and returns efficiently. However, outsourcing logistics doesn’t mean losing control. To ensure that a 3PL partnership delivers consistent value, businesses must track performance using key metrics and key performance indicators (KPIs).

Monitoring the right KPIs helps measure operational efficiency, identify areas for improvement, ensure service-level compliance, and maintain customer satisfaction. Below are the key metrics and KPIs every logistics operation should monitor.

1. Order Fulfillment Accuracy

Definition:

This KPI measures the percentage of orders shipped correctly, with no errors in quantity, item, or address.

Formula:

Fulfillment Accuracy (%) = (Total Accurate Orders ÷ Total Orders Shipped) × 100

Why It Matters:

Fulfillment errors directly affect customer satisfaction and brand reputation. A 3PL’s ability to consistently maintain a fulfillment accuracy rate above 99% is a hallmark of operational excellence. Tracking this KPI helps identify process gaps in picking, packing, or labeling.

2. On-Time Delivery Rate

Definition:

This measures the percentage of orders delivered within the promised delivery window.

Formula:

On-Time Delivery (%) = (Orders Delivered On Time ÷ Total Orders Delivered) × 100

Why It Matters:

Timely delivery is a key driver of customer loyalty. Delays may occur due to warehouse inefficiencies, carrier issues, or inaccurate lead time estimates. Monitoring on-time performance helps ensure that your 3PL maintains reliable delivery commitments and aligns with your service level agreements (SLAs).

3. Order Cycle Time

Definition:

Order cycle time is the average time it takes from when an order is placed until it is delivered to the customer.

Formula:

Order Cycle Time = (Order Delivery Date – Order Placement Date)

Why It Matters:

A shorter order cycle time indicates efficiency across warehouse operations, inventory management, and carrier performance. Long cycle times can signal bottlenecks in picking, packaging, or transportation. This KPI is vital for businesses competing in markets where speed is a differentiator.

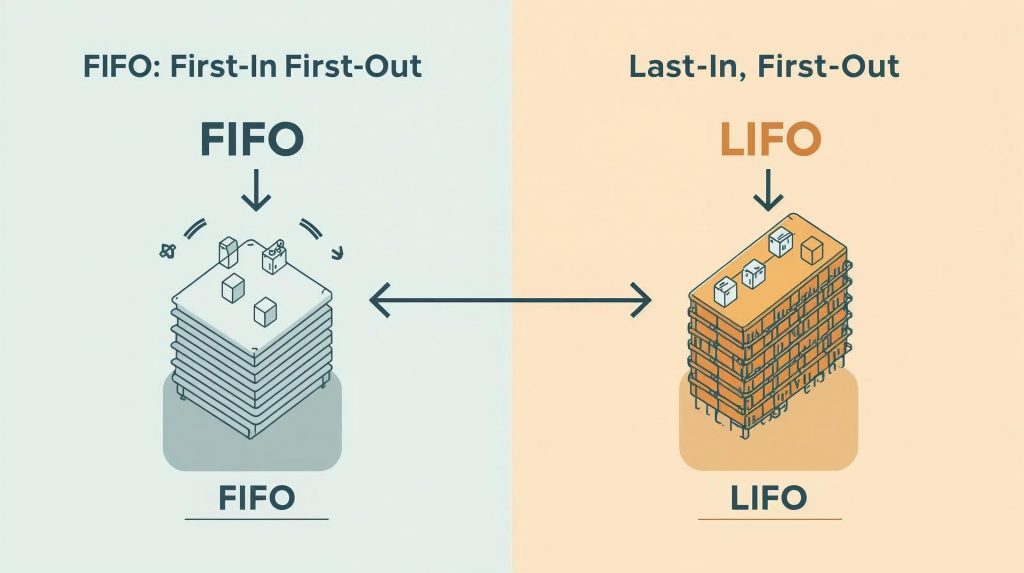

4. Inventory Accuracy

Definition:

Inventory accuracy measures how closely the recorded inventory levels match the physical count.

Formula:

Inventory Accuracy (%) = (Counted Inventory ÷ Recorded Inventory) × 100

Why It Matters:

Accurate inventory data enables efficient order fulfillment, reduces backorders, and improves forecasting. Errors can lead to overselling, stockouts, and increased carrying costs.

5. Pick and Pack Accuracy

Definition:

This measures the percentage of orders picked and packed without errors.

Formula:

Pick Accuracy (%) = (Accurate Picks ÷ Total Picks) × 100

Why It Matters:

Errors in the picking or packing process lead to returns, re-shipments, and dissatisfied customers. Monitoring this KPI ensures the 3PL maintains strict quality controls and uses technology like barcode scanning and WMS (Warehouse Management Systems) for precision.

6. Return Rate and Return Processing Time

Definition:

The return rate represents the percentage of shipped orders returned by customers. Return processing time measures how long it takes to inspect, restock, or dispose of returned items.

Formulas:

- Return Rate (%) = (Returned Orders ÷ Total Orders Shipped) × 100

- Return Processing Time = Time from Return Receipt to Resolution

Why It Matters:

High return rates may indicate issues with product quality or fulfillment accuracy. Efficient returns management is critical for customer trust, especially in e-commerce. A capable 3PL should have streamlined reverse logistics processes to minimize costs and delays.

7. Cost per Order

Definition:

This KPI calculates the average cost to fulfill one order, including labor, packaging, storage, and transportation.

Formula:

Cost per Order = Total Fulfillment Cost ÷ Number of Orders Shipped

Why It Matters:

Tracking fulfillment costs helps evaluate 3PL efficiency and profitability. A rising cost per order without a corresponding increase in service quality indicates inefficiency. Comparing this across 3PL providers can help identify the most cost-effective partner.

8. Shrinkage Rate

Definition:

This tracks the percentage of items damaged or lost during storage

Formula:

Shrinkage Rate (%) = (Damaged/lost Items ÷ Total Items Shipped) × 100

Why It Matters:

Product damage/lost leads to losses, replacements, and dissatisfied customers. Consistently high shrinkage rates can point to poor handling or unsafe storage practices. A 3PL’s ability to consistently maintain a shrinkage rate below 1% is a hallmark of operational excellence. At Homart, we’re raising the bar with Zero Shrinkage Guarantees — a promise that every unit you send to our warehouse will be accounted for!

https://shorturl.fm/fse2m

https://shorturl.fm/zAFl5

https://shorturl.fm/DByBf

https://shorturl.fm/Yk1yF

Promote our brand and watch your income grow—join today!

Start earning passive income—become our affiliate partner!

Be rewarded for every click—join our affiliate program today!

Earn passive income this month—become an affiliate partner and get paid!